Optimal Scheduling for Restaurant Hood Ventilation

Proper scheduling of restaurant hood ventilations is essential for maintaining air quality, ensuring compliance, and optimizing kitchen operations. Timing depends on operational hours, kitchen activity levels, and maintenance schedules.

Performing ventilation checks and maintenance during non-operational hours minimizes disruption and ensures systems are functioning optimally during busy periods.

Scheduling ventilation inspections before busy meal times helps maintain air quality and prevents odors from affecting customer experience.

Routine ventilation system checks are best performed at set intervals, such as weekly or monthly, to ensure continuous compliance and safety.

After thorough cleaning of kitchen exhaust components, ventilation systems should be tested and calibrated to ensure proper operation.

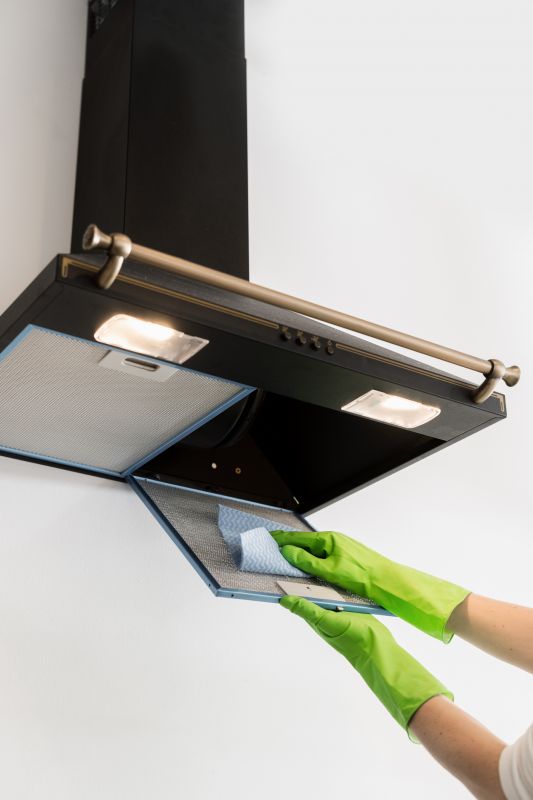

Technicians inspecting a restaurant hood ventilation system.

Technicians performing maintenance during non-operational hours.

Cleaning kitchen exhaust hoods to ensure optimal airflow.

Ways to make Restaurant Hood Ventilations work in tight or awkward layouts.

Popular materials for Restaurant Hood Ventilations and why they hold up over time.

Simple add-ons that improve Restaurant Hood Ventilations without blowing the budget.

High-end options that actually feel worth it for Restaurant Hood Ventilations.

Finishes and colors that play nicely with Restaurant Hood Ventilations.

Restaurant hood ventilations play a crucial role in maintaining indoor air quality by removing smoke, heat, grease, and odors generated during cooking. Properly functioning ventilation systems help prevent grease buildup, reduce fire hazards, and comply with health and safety regulations. Statistics indicate that regular maintenance can improve airflow efficiency by up to 30%, reducing energy costs and prolonging system lifespan.

Effective ventilation is vital for restaurants to ensure a safe and comfortable environment for staff and patrons. Systems should be inspected and serviced regularly, especially before busy periods, to prevent malfunctions that could impact operations or safety. Advances in ventilation technology include sensors that monitor airflow and grease accumulation, alerting staff when maintenance is needed.

Close-up of exhaust fans and ductwork.

Professional cleaning of a restaurant hood.

Sensors measuring air quality in a commercial kitchen.

Technician inspecting ventilation system components.

Little measurements that prevent headaches on Restaurant Hood Ventilations day.

A 60-second routine that keeps Restaurant Hood Ventilations looking new.

A frequent mistake in Restaurant Hood Ventilations and how to dodge it.

Small tweaks to make Restaurant Hood Ventilations safer and easier to use.

| Aspect | Details |

|---|---|

| Optimal Timing | Off-peak hours, before peak times, or scheduled maintenance intervals. |

| Frequency | Regular inspections should be scheduled monthly or quarterly. |

| Operational Benefits | Improves air quality, reduces fire risk, and enhances system efficiency. |

| Regulatory Compliance | Timely ventilation maintenance helps meet health and safety standards. |

| Impact of Delays | Increased grease buildup, higher fire risk, and system failures. |

Scheduling restaurant hood ventilations at appropriate times ensures continuous safety, compliance, and operational efficiency. Regular maintenance and timely inspections are key to preventing system failures and maintaining air quality in busy kitchen environments.

A commercial kitchen exhaust fan operating efficiently.

Cleaning grease filters as part of maintenance.

Device measuring air quality in a restaurant kitchen.

Lower-waste or water-saving choices for Restaurant Hood Ventilations.

The short, realistic tool list for quality Restaurant Hood Ventilations.

Rough timing from prep to clean-up for Restaurant Hood Ventilations.

Quick checks and paperwork to keep after Restaurant Hood Ventilations.

Examples that show the impact a good Restaurant Hood Ventilations can make.

Interested in optimizing restaurant hood ventilation schedules or systems? Filling out the contact form can provide tailored solutions to meet specific operational needs and ensure compliance with safety standards.